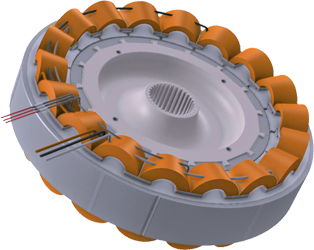

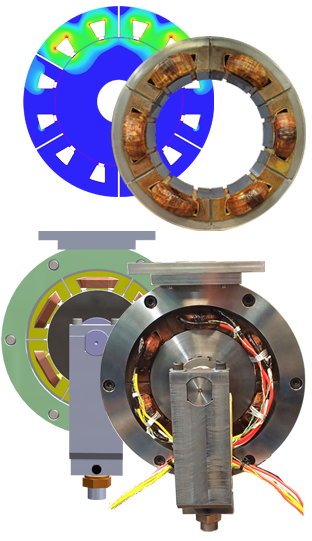

Active Magnetic Bearings

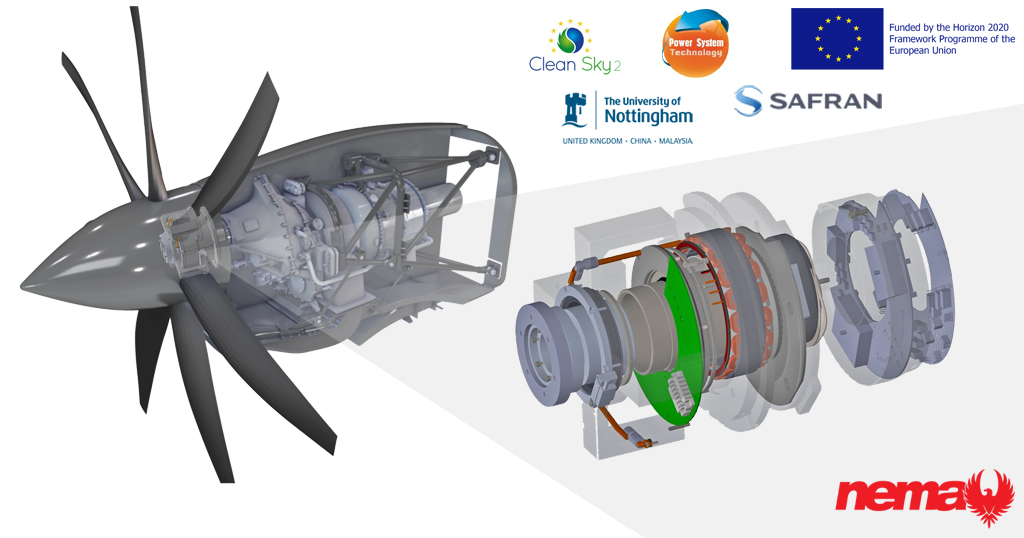

NEMA are leading the development of active magnetic bearing technology for aerospace applications.

This complements our existing high-speed electric motor/generator offerings.

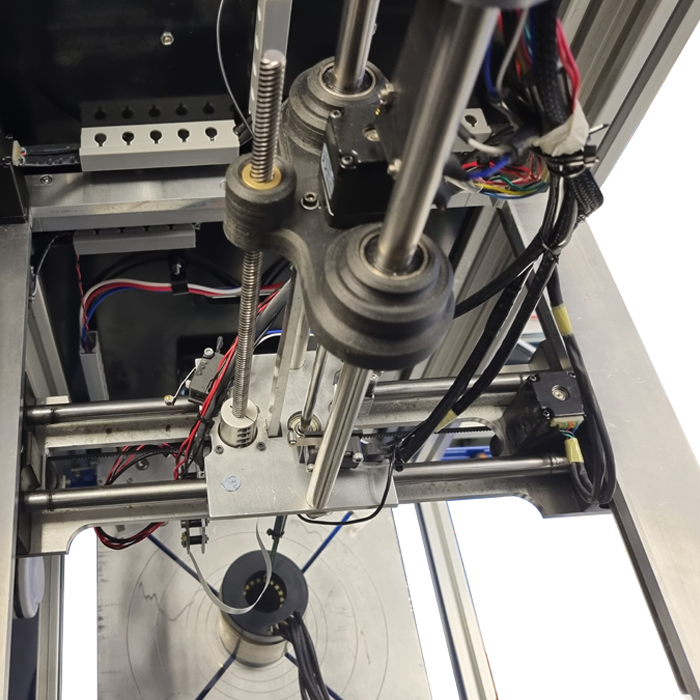

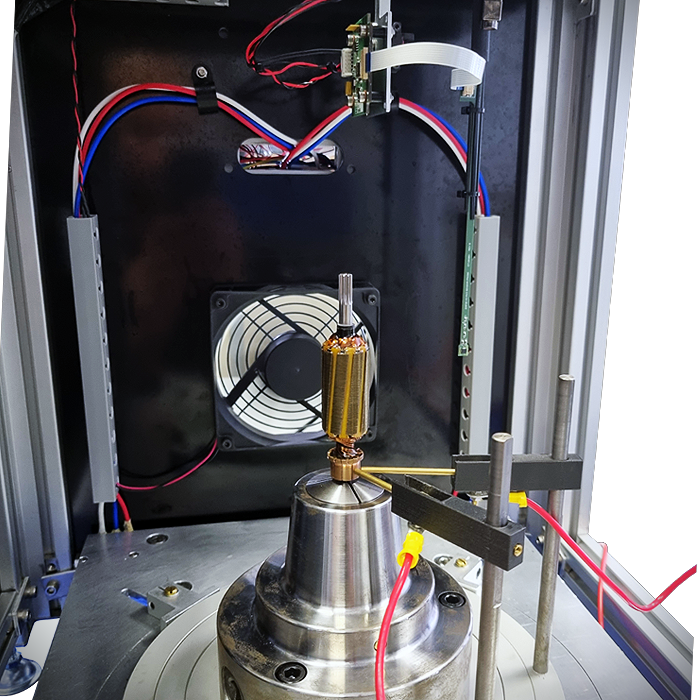

• Non-contact levitation eliminates friction and wear

• Active damping gives critical speed immunity

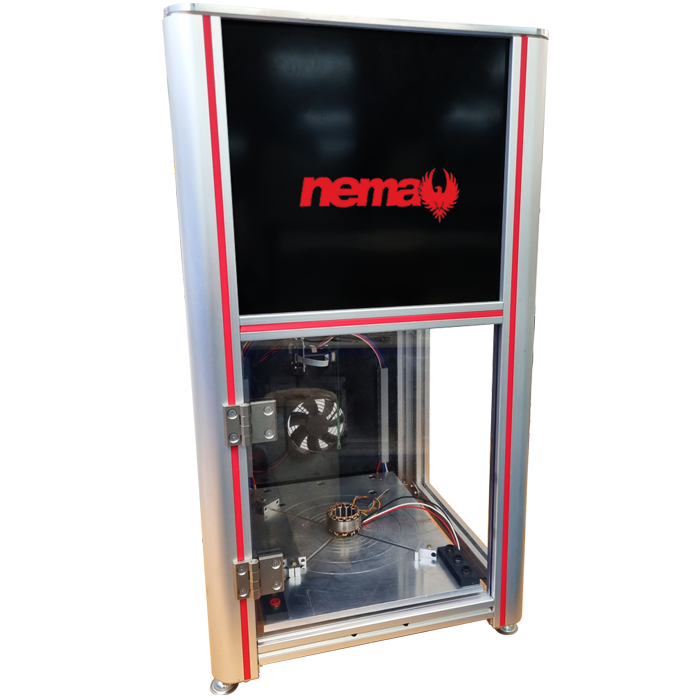

• Actuators experimentally validated (TRL4)

• 40 kW, 100 kRPM system demonstration by 2027 (TRL6)