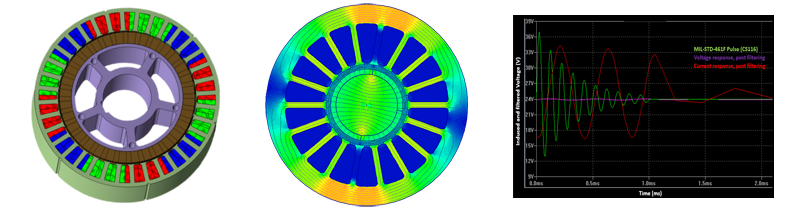

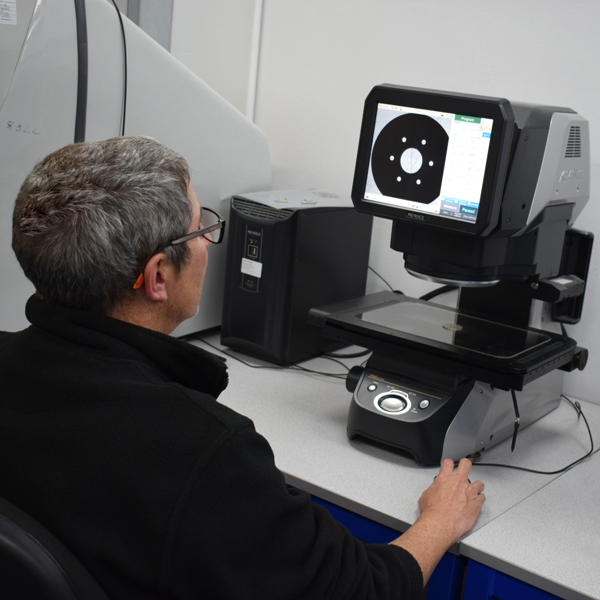

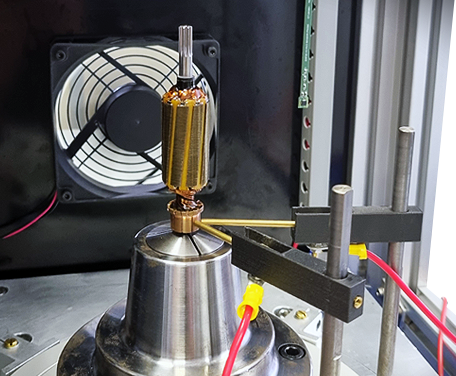

NEMA has extensive experience in the development of new products for challenging environments with the capability and approvals to design and develop electric motors, electro-mechanical actuators and components for a wide variety of applications. We also specialise in prototype and development production. Our in house manufacturing techniques and facilities are ideal for prototype manufacture right through to serial production.

Every project undertaken is unique, resulting in the constant improvement of our skills and manufacturing techniques. Our engineers work closely with our clients and suppliers to ensure the efficient technical realisation of projects.